Il tessuto Oxford, noto anche come trama Oxford, è un tessuto intrecciato, dalla struttura fitta e molto versatile, originario dell'Inghilterra intorno al 1900. Il suo nome deriva dal suo utilizzo nelle camicie eleganti presso l'Università di Oxford.

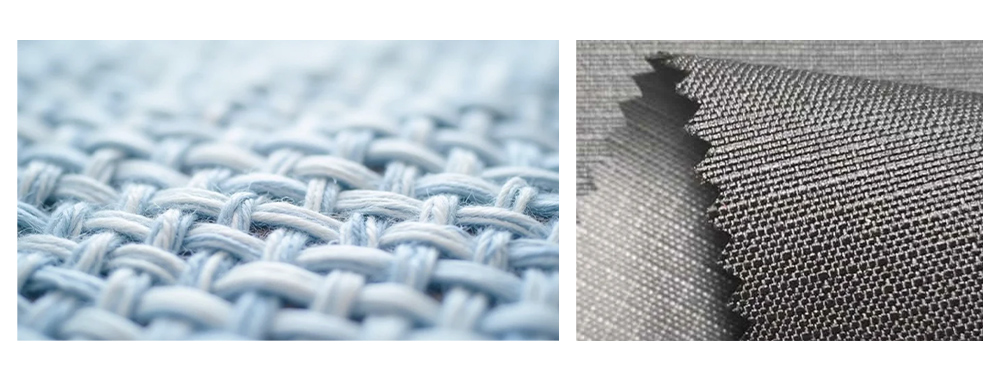

La sua caratteristica più distintiva è l'esclusiva "trama a canestro 2x2", in cui due fili di ordito si intrecciano con due fili di trama per creare una piccola trama a quadretti che conferisce al tessuto una certa robustezza. Questa costruzione conferisce al tessuto Oxford la sua caratteristica combinazione di durevolezza, traspirabilità, resistenza alle pieghe e una mano relativamente morbida.

• Tessuto Oxford è il termine più ampio che comprende qualsiasi tessuto intrecciato con questa specifica struttura a intreccio.

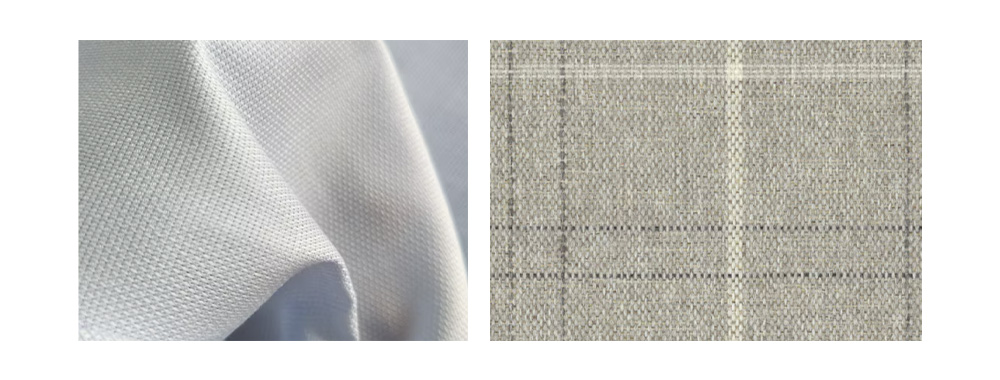

• La filatura Oxford (o "Oxford shirting") si riferisce normalmente alle versioni più leggere e morbide del tessuto Oxford destinate alle camicie, solitamente realizzate in cotone o miscele di cotone e apprezzate per il comfort e l'aspetto.

In breve: tutta la filatura Oxford è tessuto Oxford, ma non tutti i tessuti Oxford sono classificabili come filatura Oxford. Un tessuto Oxford in poliestere pesante e rivestito, utilizzato per i bagagli, ad esempio, non verrebbe mai definito "filatura Oxford".

• Per le camicie: scegli cotone o un Oxford misto cotone ad alto titolo; deve essere morbido e flessibile.

• Per borse o attrezzature per esterni: scegliere poliestere/nylon Oxford rivestito e controllare il denari (D) e il tipo di rivestimento.

Denaro Indica lo spessore del filato. I valori più comuni sono 300 D, 600 D, 900 D, 1.000 D, 1.200 D, 1.680 D, ecc. Maggiore è il denari, più spesso è il filato e più pesante, resistente e resistente all'abrasione è il tessuto. Una borsa da 1.680 D, ad esempio, sarà estremamente robusta ma anche notevolmente più pesante.

Rivestimento determina la resistenza all'acqua, la resistenza all'abrasione e altre proprietà protettive.

il classico motivo a quadri intrecciati è il segno distintivo; anche su tessuti rivestiti il motivo dovrebbe essere visibile.

3.1 Durata e resistenza: tLa fitta trama a canestro rende il tessuto estremamente robusto e resistente all'abrasione, tanto che si strappa solo in caso di notevole sollecitazione.

3.2 Traspirabilità: rispetto a molti tessuti rivestiti completamente sintetici, l'Oxford naturale o misto consente il passaggio di molta più aria e umidità.

3.3 Resistenza alle pieghe: il peso leggermente più pesante e la superficie testurizzata lo aiutano a resistere meglio alle pieghe rispetto al cotone a trama semplice.

3.4 Comfort morbido: Sebbene intrinsecamente robusto, l'Oxford rifinito, in particolare le versioni in cotone, può essere reso sorprendentemente morbido, risultando così confortevole a contatto con la pelle.

3.5 Facile manutenzione: il tessuto è generalmente lavabile in lavatrice e si asciuga rapidamente, richiedendo poca manutenzione speciale.

Caratteristiche: la versione classica, più traspirante, più confortevole a contatto con la pelle.

Utilizzi: camicie di alta qualità, abbigliamento da lavoro, pantaloni casual.

Caratteristiche: altissima tenacità, peso ridotto, asciugatura rapida, resistente all'abrasione e alla muffa; traspirabilità inferiore.

Utilizzi: bagagli, tende, attrezzatura da esterno, coperture per veicoli, borse portaoggetti.

Caratteristiche: unisce la comodità del cotone alla resistenza del poliestere, alla resistenza alle pieghe e alla facilità di manutenzione.

Usi: camicie casual da lavoro, uniformi.

Caratteristiche: due fili di ordito di colore diverso intrecciati simultaneamente per creare un audace motivo a quadri bicolore; molto decorativo.

Usi: camicie alla moda, zaini in tessuto oxford, tappezzeria.

Caratteristiche: vengono aggiunti spandex o altri filati elastomerici, che conferiscono al tessuto elasticità e recupero controllati.

Utilizzi: indumenti per attività all'aperto, zaini sportivi che necessitano di libertà di movimento.

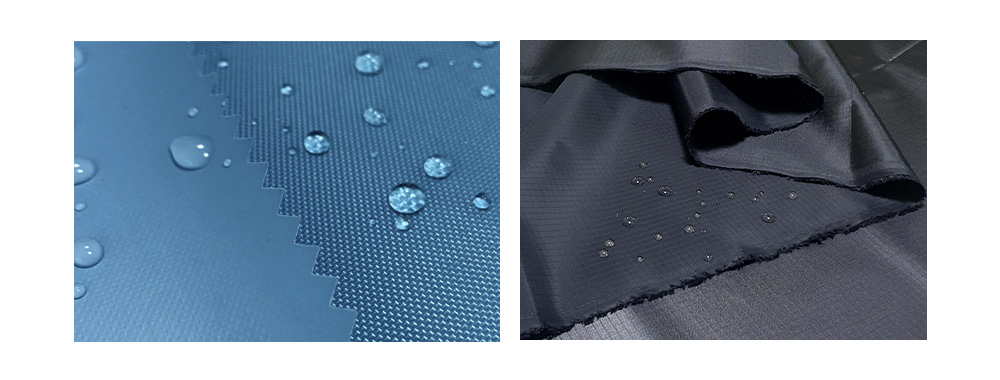

Caratteristiche: il tessuto di base è rivestito o laminato con PVC, PU, ecc., conferendogli proprietà impermeabili, antimacchia o addirittura ignifughe.

Utilizzi: materiale primario per coperture di valigie, trolley, zaini da esterno, tende da sole e tende.

Grazie ai suoi innumerevoli vantaggi, il tessuto Oxford è presente ovunque nella vita quotidiana. Il suo mercato più grande ed emblematico, tuttavia, è quello dei bagagli e delle borse: quasi ogni valigia, trolley, zaino, borsone e custodia per laptop si affida al tessuto Oxford rivestito, di una qualità o dell'altra. In questo settore, i punti di forza del tessuto si manifestano principalmente in due modi:

Un rivestimento fa molto di più che aggiungere colore: conferisce al tessuto di base una serie di proprietà completamente nuove.

• Caratteristiche: l'opzione più vecchia ed economica; la pellicola è relativamente spessa e rigida, offrendo una buona resistenza all'acqua.

• Sensazione al tatto: decisamente "plastica" e può irrigidirsi quando fa freddo.

• Usi: valigie di prima generazione, borse da viaggio economiche e borse portautensili; ora sostituite da finiture più avanzate.

Panoramica: la finitura dominante oggi. Viene applicata in due modi: laminazione a secco (una pellicola in PU viene applicata direttamente sul tessuto di base) o laminazione a umido (una pellicola in PU preformata viene incollata al tessuto).

Vantaggi: mano più morbida del PVC, maggiore resistenza all'abrasione e allo strappo, impermeabilità affidabile, rimane flessibile anche in caso di freddo ed è più ecologico.

Usi: l'Oxford rivestito in PU è il tessuto di rivestimento ideale per la maggior parte delle valigie, degli zaini e delle borse da giorno moderne di fascia media e alta. zaini scolastici per bambini e custodie per laptop.

Caratteristiche: pellicole ad alta tecnologia come il TPU. La membrana blocca l'acqua liquida dall'esterno, consentendo al contempo al vapore acqueo di fuoriuscire all'interno della borsa, mantenendo l'interno asciutto e confortevole.

Utilizzi: zaini da esterno di alta qualità, borse da ciclismo, zaini da alpinismo, dove sia la protezione dalla pioggia che la ventilazione sono essenziali.

Rivestimento anti-UV: protegge il tessuto dalla degradazione dei raggi ultravioletti; utilizzato su tende da sole e zaini da esterno.

Rivestimento ignifugo: soddisfa i rigorosi requisiti di sicurezza per le borse industriali o militari.

Rivestimento vintage/graffiato: goffrato o stampato per creare un aspetto vissuto e strutturato che nasconde i graffi; popolare sugli zaini alla moda.

Il numero di denari determina le caratteristiche fisiche del tessuto ed è il primo dato da controllare al momento dell'acquisto.

• Caratteristiche: leggero come una piuma, sottile e flessibile.

• Usi: carrelli della spesa pieghevoli, fodere per borse, ovunque sia importante il peso ridotto.

• Caratteristiche: il punto ideale per le borse; abbastanza solide da mantenere la forma, abbastanza resistenti per l'uso quotidiano, ma comunque ragionevolmente leggere.

• Usi: zaini, borsoni da viaggio, borse a tracolla, borse portautensili. Il tessuto Oxford 600 D è il cavallo di battaglia del settore.

• Caratteristiche: visibilmente robusto, estremamente resistente all'abrasione e allo strappo, ma notevolmente più pesante.

• Usi: valigie professionali resistenti, zaini da lavoro, borse militari, custodie per armi, borse tecniche, borse per macchine fotografiche, sacchi per carichi ingombranti. Il tessuto Oxford 1680D è diventato sinonimo di "a prova di bomba"; marchi premium come TUMI realizzano la maggior parte della loro linea con questo materiale.

• Cambiamento ecologico: Il tessuto Oxford tessuto in poliestere riciclato (RPET) e rifinito con rivestimenti in PU o biosolventi a base d'acqua sta rapidamente sostituendo le versioni convenzionali a base di olio.

• Alleggerimento: Filati ad alta tenacità e architetture di trama più dense consentono ai tessuti a bassa denaratura di garantire la resistenza allo strappo un tempo riservata ai tessuti da 1.000 D+, risparmiando grammi preziosi da ogni confezione.

• Incrocio di moda: quadri, jacquard, tessuti fiammati effetto lino, tinte spaziali e lavaggi spogliano il tessuto della sua immagine da "abbigliamento da lavoro" e lo spostano verso l'abbigliamento da strada e la valigeria di alta qualità.

• Integrazione intelligente: Oxford sta diventando un substrato: termosaldato con tag NFC per il tracciamento dei bagagli, oppure laminato su pellicole solari flessibili che trasformano gli zaini in caricabatterie autonomi.

Nel mondo delle borse, il tessuto Oxford non è più "solo tessuto". Ottimizzando quattro variabili chiave (filato di base (poliestere o nylon), spessore del filato, densità di trama e tecnologia di rivestimento), i produttori trattano i tessuti come una ricetta, personalizzando esattamente le prestazioni di cui una determinata borsa ha bisogno. Questa versatilità e convenienza senza pari hanno reso Oxford un prodotto adatto a ogni segmento, dai pendolari quotidiani all'equipaggiamento da spedizione. Ottieni una guida completa da Synberry.

| Autore | ||||||

|

Diritto d'autore

@2024 Synberry Bag & Package Products Co.,Ltd Tutti i diritti riservati

.

RETE SUPPORTATA

RETE SUPPORTATA